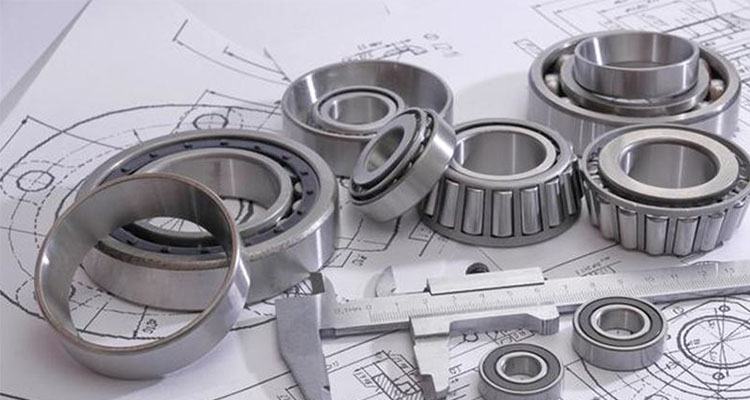

Slewing bearings

ZYSINT can offer five types of slewing ring bearings, including single row four point contact ball slewing bearing, double row different ball diameter slewing bearing, single row cross roller slewing bearing,roller&ball combination slewing bearing and three-row cylindrical roller slewing bearing.

Keywords:

Slewing bearings

Series:

Product Details

Slewing bearing types:

The slewing bearings produced by our company can be divided into: single row four point contact ball slewing bearings, single row crossed roller slewing bearings, double-row different-diameter ball slewing bearings, three-row cylindrical roller combined slewing bearings, ball-roller combined slewing bearings, etc. Each type of bearing is divided into toothless type, external tooth type and internal tooth type according to whether it has teeth and the position of the teeth.

Single row four point contact ball slewing bearing

Features: It has a high dynamic load bearing capacity and can withstand radial force, axial force and large overturning moment. This type of bearing is mainly used in lifting equipment, hoisting equipment, general engineering machinery and other fields.

Single row crossed roller slewing bearings

Features: It can withstand large radial forces, medium axial forces and overturning moments, and can meet the requirements of small clearance or "zero" clearance. This type of bearing is mainly used in lifting equipment, hoisting equipment and general engineering machinery.

Double row different-diameter ball slewing bearings

Features: This type of bearing has a simple structure and strong static load capacity. This type of bearing is mainly used in situations where the load position and direction change rapidly and rotate continuously, such as: marine hoisting equipment, mining hoisting equipment and material transportation, etc.

Three row cylindrical roller combined slewing bearing

Features: It has high load-bearing capacity. Various loads are borne by different raceways and roller groups respectively. Therefore, under the same force conditions, the bearing diameter can be greatly reduced, making the main machine more compact. It is mainly used in lifting equipment, hoisting machinery, mining equipment and material transportation, offshore operations and general engineering machinery.

Ball-roller combined slewing bearings

Features: It can bear high axial load and small overturning moment, and usually has a large diameter. It is mainly used in mining and material processing industries.

Production capacity of Slewing Bearing

The production workshop covers an area of over 30,000 square meters and has more than 200 sets of various production equipment.

Technical Advantages

Our large bearing R&D team has long been committed to fundamental theoretical research such as bearing and shaft system simulation analysis, helping customers from product design onwards with technical support including scheme design, theoretical calculation, simulation analysis, and providing complete solutions for transmission systems.

Materials and Heat Treatment Process Research

We possess an internationally recognized Austrian Aichelin heat treatment production line. Through research on the properties of different materials and heat treatment processes, we continuously improve heat treatment parameters, forming a complete set of heat treatment process methods that effectively enhance the impact resistance and fatigue resistance of materials.

Quality control of Slewing Bearing

It maintains a leading domestic position in bearing fundamental theory, lubrication technology, design analysis, material application and failure analysis, testing technology and technical standards. Its products and services have obtained ISO9001, AS9100, and IATF16949 quality certifications.

Materials of Slewing Bearing

To ensure optimal performance and reliability, ZYSINT slewing bearings are manufactured using carefully selected materials for each component:

⯁ Material of Slewing Ring

The slewing rings are primarily made from 42CrMo steel, which undergoes surface quenching to enhance the hardness and wear resistance of the raceway. Depending on the customer's requirements and the specific working conditions, other types of surface-quenched steels can also be utilized to meet various application needs.

⯁ Material of Rolling Elements

The rolling elements used in ZYSINT slewing bearings are made from high-quality bearing steels such as GCr15 or GCr15SiMn, offering excellent fatigue resistance and hardness to ensure long service life under demanding conditions.

⯁ Material of Cage

A variety of cage designs are available, including integrated cages, segmented cages, and spacers, each selected according to the application and bearing structure.

For integrated and segmented cages, the materials commonly used are 20 steel or ZL102 cast aluminum alloy.

Spacers are typically manufactured from materials such as polyamide 1010 resin, ZL102 aluminum bronze, QA110-3-1.5 aluminum bronze, or GRPA66-25 nylon, chosen for their strength, wear resistance.

⯁ Material of Sealing Ring

The sealing rings are made from Nitrile Butadiene Rubber (NBR), which provides excellent resistance to oil, abrasion, and a wide range of temperatures, ensuring effective sealing performance in various environments.

Series Related Products

Angular contact ball bearings have a high limit speed and can bear radial loads and axial loads at the same time, as well as pure axial loads.

The Agri Hub Bearing is a fully integrated wheel hub bearing system that is lubricated and sealed for life.

300XDJ05G50 Milling Spindles/motorized spindle with discount

The XDJ series milling spindles have the functions of automatic broach release, precise control of speed and accurate stop. They can process high-speed milling and engraving, thus they are widely used in the processing of conventional parts, tools, molds and wood workpieces.

Thin section bearings, are a specially designed bearing, which is characterized by thin inner and outer ring wall thickness, small cross-sectional dimensions, light weight, and high rigidity and load-bearing capacity.

Our company has accumulated rich experience in the design, performance regulation and processing of cages of various materials.

Our company is a professional manufacturing company integrating the research and development, production and sales of bearing rings.

The company can provide a full range of silicon nitride ceramic balls and zirconium oxide ceramic balls for bearings with specifications ranging from Φ0.8mm to Φ31.5mm.

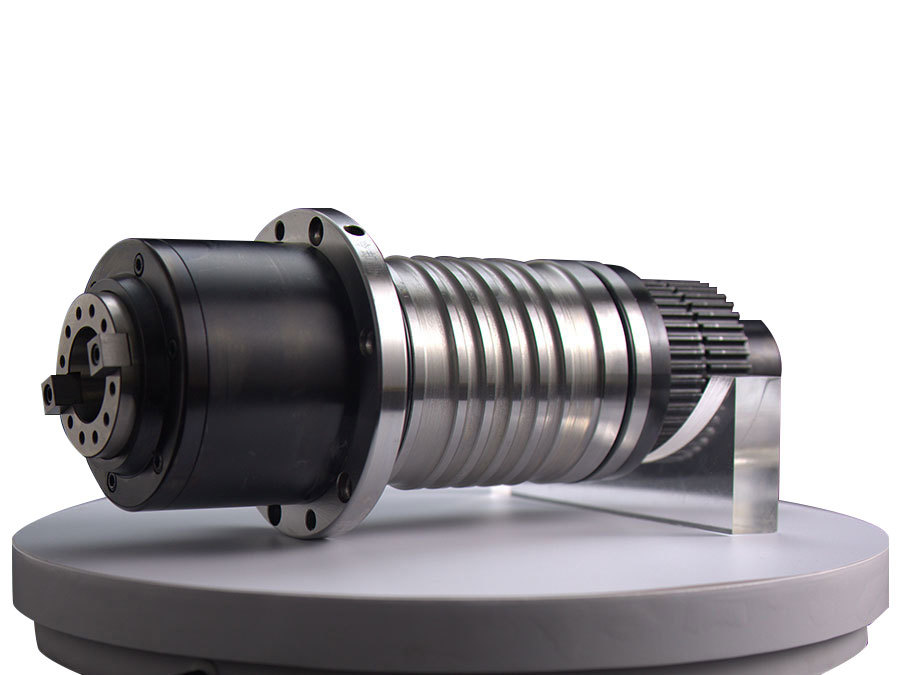

High speed spindles for rotation-rolling

High speed spindles for rotation-rolling have LD series and they are widely used for machining internal thread copper tubes for heat exchange of air conditioning equipment.

Rolling linear guides are composed of guide rails, sliders, steel balls, return devices, cages, sealing devices, etc.

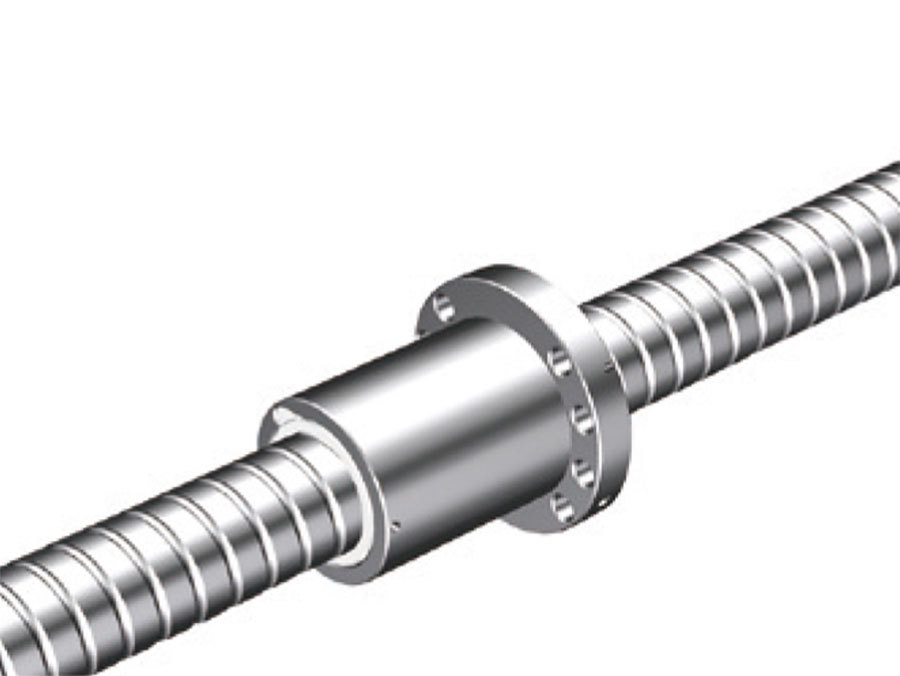

The ball screw pair is a mechanical element composed of a screw, a nut, a ball and other parts. Its function is to convert rotational motion into linear motion or convert linear motion into rotational motion.

Mechanical spindles include XP, XPJ, CPJ and other series, with belt drive and direct connection modes.

The milling spindles have XD, XDS and XDJ series. They have the functions of automatic broach release, precise control of speed and accurate stop.

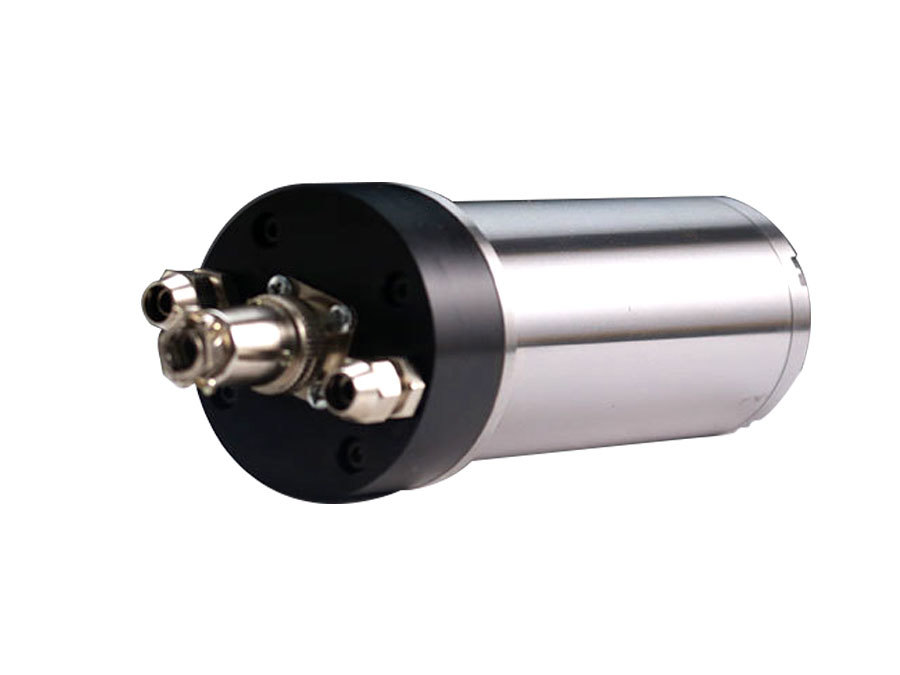

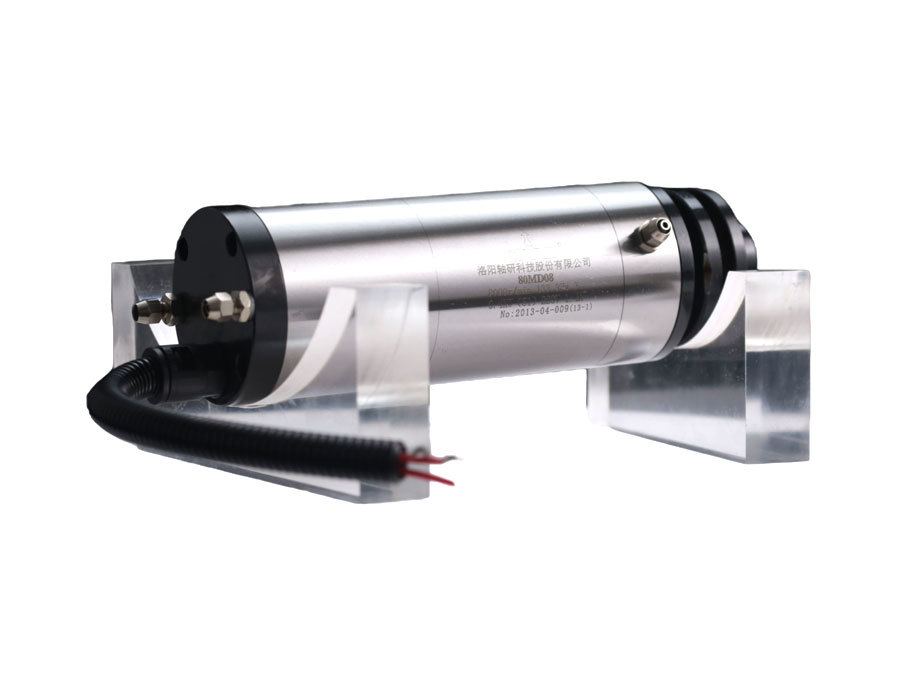

The grinding spindles have MD, MDF, MDT, MDS, MDK series. Grinding spindles have the characteristics of high precision, high speed, high power and high rigidity.

Bearing radial clearance measuring instrument X095JC/X092JC/X093JC

The radial clearance of rolling bearings is one of the important quality indicators of bearings and an important factor affecting the vibration, noise and life of bearings.

Testing machine (material field)

Major customers are lubricant oil and grease manufacturers and the steel industry.

Testing machine (automotive industry)

Covering automobile engine rocker arms, automobile wheel hub units, clutch brake unit bearings.

Testing machine (bearing industry)

Covering all types and sizes of bearings. The main customers are domestic and foreign bearing manufacturers.

Testing machine (railway field)

Covers rail transit traction motor bearings, full suspension bearings, axle box bearings, and gearbox bearings.

Testing machine (wind power field)

Covering wind turbine main engine yaw and pitch bearings, main shaft bearings, gearbox bearings, and generator bearings.

Our company can provide cold rolling processing line, bearing ring grinding line, cold rolling machine, roller superfinishing machine, groove superfinishing machine, grinding machine, non-standard grinders and other products.

ZYSINT can offer five types of slewing ring bearings, including single row four point contact ball slewing bearing, double row different ball diameter slewing bearing, single row cross roller slewing bearing,roller&ball combination slewing bearing and three-row cylindrical roller slewing bearing.

The internal structure of the cross roller bearing adopts rollers arranged perpendicularly at 90 degrees to each other.

We can offer YRT series, YRTS series, ZKLDF series, YRTM series, YRTSM series rotary table bearings.

Y90 series High speed roundness measuring instrument

The roundness value of bearing parts directly affects the processing datum between processes as well as the rotation accuracy, noise, vibration, life and assembly quality of the bearing finished product.