Wind power industry

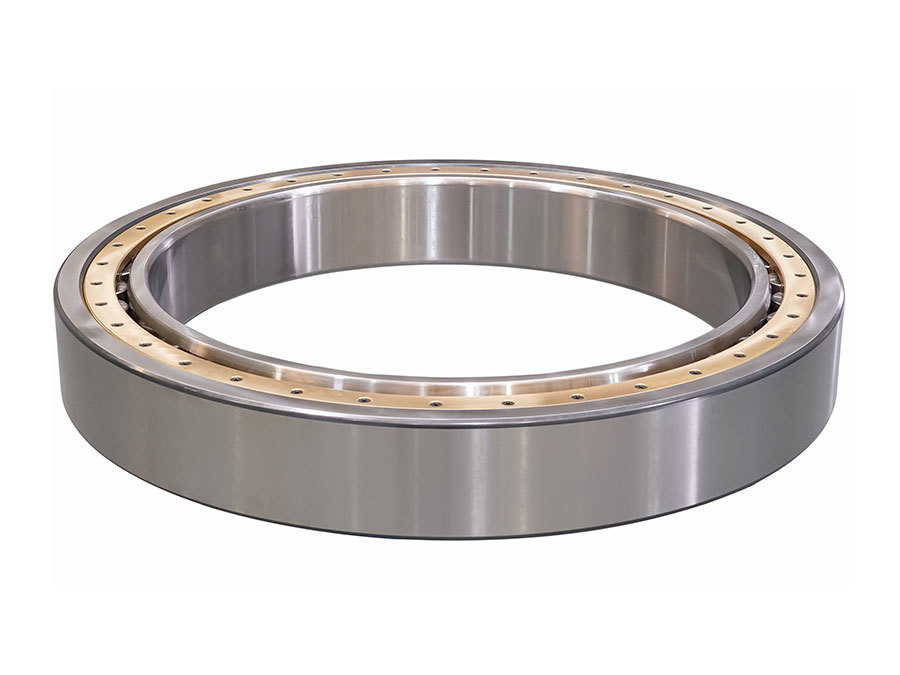

Gearbox bearings

The products include all types of gearbox bearings, including deep groove ball bearings, cylindrical roller bearings, full complement cylindrical roller bearings, double row tapered roller bearings, spherical roller bearings, thrust spherical roller bearings, four-point contact ball bearings, etc. The accuracy can reach P5 level, and some can reach P4 level. The basic rated life is ≥100,000 hours, among which the life of offshore wind power gearbox bearings is not less than 25 years, and the temperature rise is not higher than 85°C. We have now completed the research and development of a full range of domestic 8MW wind turbine gearbox bearings, and have completed installation and application.

Spindle bearings

The main shaft of the wind turbine supports the hub and blades and transmits torque to the speed increaser. The spindle bearing is a key component of the main transmission chain system of a wind turbine. It not only has to withstand wind loads, but also the gravity loads of the main shaft and speed increaser, and its working conditions are complex. Depending on factors such as the unit power, overall structure, operating conditions, manufacturing cost, and installation process of the wind turbine, the spindle bearings need to adopt different configurations. Product types include: spherical roller bearings (SRB), tapered roller bearings (TRB), three-row cylindrical roller bearings (CRB); the rotation accuracy of spindle bearings for large wind turbines (above 5MW) can reach P5 level, and some reach P4 level. We have successfully developed spindle bearings for wind turbines below 25MW.

Yaw and pitch bearings

The yaw bearing is installed at the top of the tower and the bottom of the nacelle. It bears the entire weight of the wind turbine's main drive system and is used to accurately and timely adjust the windward direction of the wind turbine. The pitch bearing combines the blades with the hub and adjusts the windward angle of the blades to the optimal state according to the wind direction. Yaw and pitch bearings must have sufficient strength and the ability to withstand the combined effects of axial force, radial force, and overturning moment. It is required to have smooth operation, small starting torque, good lubrication, corrosion resistance and sealing performance. The yaw and pitch bearings are extra-large slewing bearings with an outer diameter of approximately 0.5 to 4.5 m and a weight of 0.5 to 6.0 t. The structural forms of yaw bearings mainly include single-row four-point contact ball slewing bearings (toothless, internally geared, externally geared) and double-row four-point contact ball slewing bearings (toothless, internally geared, externally geared). Pitch bearings mostly use double-row same-diameter four-point contact ball slewing bearings (toothless, internally geared).

Intelligent monitoring system for wind turbine main bearings

Independently developed by our company, the intelligently monitored system for wind power main bearings is designed for direct-drive or semi-direct-drive wind turbines. The system adopts a TRB+TRB (Tapered Roller Bearing + Tapered Roller Bearing) configuration. This system addresses three major challenges: 1. Main Bearing Installation: Using integrated sensors, the system detects whether the bearing is installed at an tilt and verifies if the target operational clearance has been accurately achieved. 2. Real-Time Operational Monitoring: It continuously tracks key performance indicators such as temperature, displacement, vibration, and rotational speed, providing immediate feedback to ensure timely detection of abnormal operating conditions. 3. Remaining Service Life Prediction: By integrating reliability theory and condition perception data into computational models, the system enables real-time forecasting of the bearing’s remaining service life.