-

-

Precision bearings

-

Angular contact ball bearings

-

Crossed roller bearings

-

Tapered roller bearings

-

Slewing bearings

-

Ball screw support bearings

-

Rotary table bearings

-

Thin-wall bearings

-

-

Bearing related

-

Bearing parts

-

Spindle

-

Bearing testing machine

-

Bearing measuring instrument

-

Bearing processing equipment

-

-

Oil industry

Bearings for hooks, turntables, cranes

The main bearing types are: 1. Hook bearings are mainly thrust roller bearings. 2. The bearings for the turntable are mainly cross roller turntable bearings. 3. Cylindrical roller bearings are mainly used in the crane winch parts.

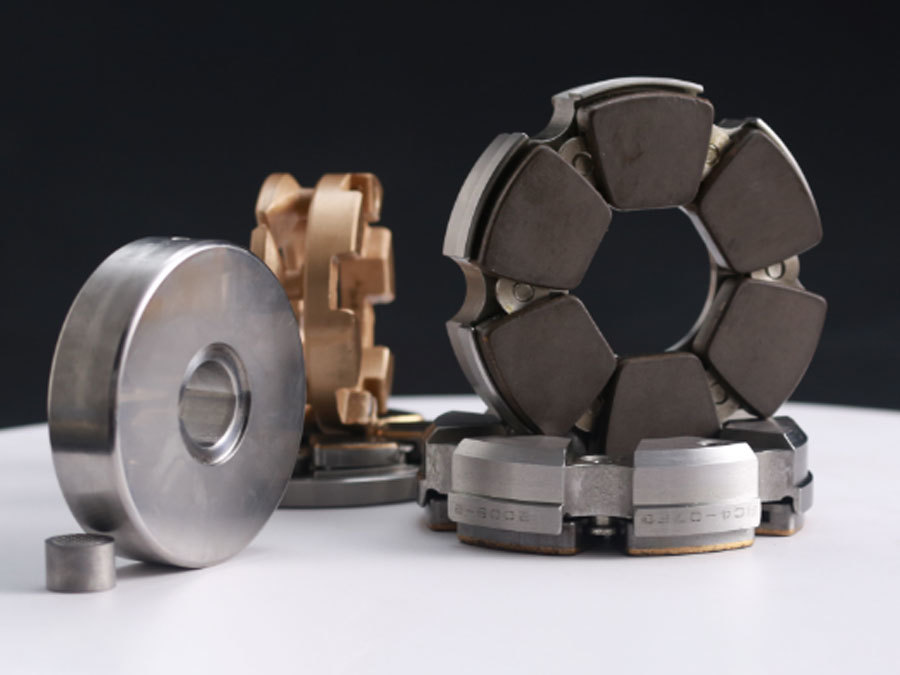

Liner hanger bearings

Liner hanger bearings are mainly used in the field of petroleum cementing. The bearing adopts full complement conical convex roller bearings, and uses finite element analysis to optimize the structure and main parameters of the bearing body, reduce stress concentration, improve bearing capacity. The bearing uses special sealing device to prevent mud from entering the bearing, and fills high temperature grease to ensure high temperature lubrication. The bearing can prevent the influence of uneven bearing load and overturning load, and it has higher axial load capacity and working ability in high temperature mud environment, lower rotating torque in harsh environment of high temperature and high load, and longer service life. It provides a guarantee for the reliability of the use of the rotary liner hanger.

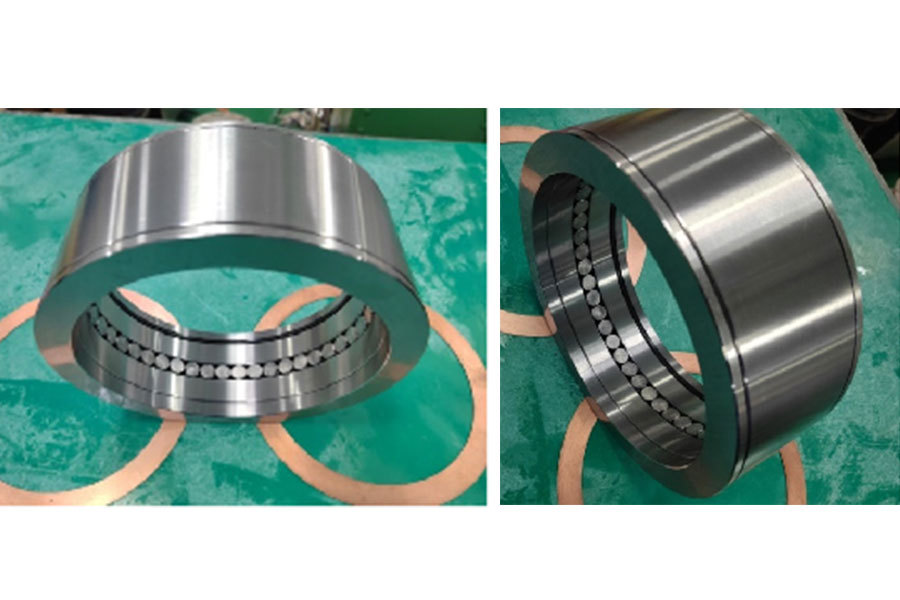

Petroleum screw drilling tool bearings

Petroleum screw drilling tool bearings are mainly used for underground power drilling tools and maintenance. Bearing types mainly include multi row thrust ball bearings and multi row thrust roller bearings.

Composite material bearings

Composite material bearings are widely used in various fields of mechanical engineering, such as aircraft, automobiles, motorcycles, printing, textiles, etc. They mainly bear radial load. Using cold-rolled steel plate as the matrix, sintered porous bronze powder as the intermediate layer, and surface is compounded with composite modified polytetrachloroethylene self-lubricating material. The special manufacturing process and steel backed porous bronze modified PTFE multi-layer composite structure make this material have excellent comprehensive mechanical properties, wear reduction and wear resistance characteristics, and good thermal conductivity.

Embedded self-lubricating bearings

Embedded self-lubricating bearings are mainly used in bridges, rollers, furnace machinery, underwater equipment, petroleum machinery, metallurgical equipment, lifting and transportation machinery, etc. They mainly bear radial load. Based on metal alloys, solid lubricants are embedded on their working surfaces to release and generate a solid lubrication film on the sliding surface during the working process, separating the worn parts and achieving the purpose of reducing friction and wear. According to different applications, embedded bearings can use high-strength brass alloys, bronze alloys, cast iron, and bimetallic materials as the matrix. Self-lubricating embedded bearings combine the characteristics of metal and non-metal, and have advantages of high load-bearing capacity, small friction coefficient, good wear resistance, and long service life.

Mud pump bearings

Mud pump bearings are mainly used in various mud pumps and fracturing pumps for drilling and petroleum machinery. The main types of mud pumps are: QDP-3000, 2800A/3300 plunger pump, 5000/7000 plunger pump, Russian pump, etc.

Hydrodynamic bearings

Hydrodynamic bearings are mainly used in submersible pump devices and motor protectors. Hydrodynamic bearings are divided into hydrodynamic radial bearings and hydrodynamic thrust bearings. The bearings mainly bear axial loads and can also bear certain impact loads. The speed of the bearing varies with the current frequency.

Share your needs with us and get an impressive collaboration and reassuring product.

Headquarter: East Wing Building, No. 121 Wutong Street, High-Tech Industrial Development Zone, Zhengzhou City, Henan Province, China

No. 1 Factory Address: No. 6 Fenghua Road, Luoyang City, Henan Province, China

No. 2 Factory Address: No. 1 Sanxi Road, Science and Technology Industrial Park, Jianxi District, Luoyang City, Henan Province, China

No. 3 Factory Address: Yibin Industrial Technology Park, Yibin District, Luoyang City, Henan Province, China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.