-

-

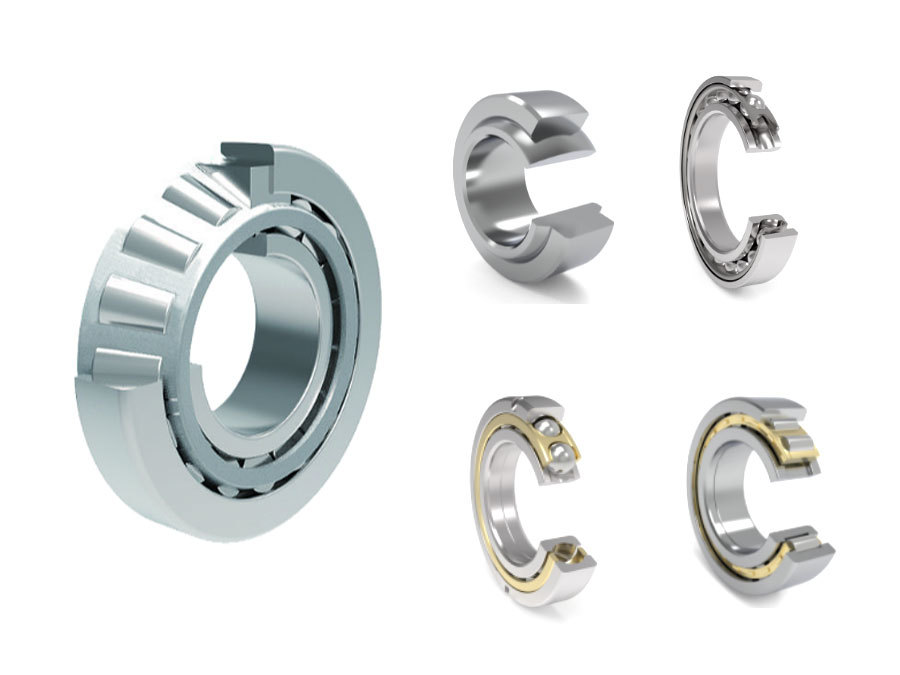

Precision bearings

-

Angular contact ball bearings

-

Crossed roller bearings

-

Tapered roller bearings

-

Slewing bearings

-

Ball screw support bearings

-

Rotary table bearings

-

Thin-wall bearings

-

-

Bearing related

-

Bearing parts

-

Spindle

-

Bearing testing machine

-

Bearing measuring instrument

-

Bearing processing equipment

-

-

Automotive industry

Tensioner bearing

Bearing features: 1. Excellent sealing performance, ensuring the normal operation of the bearing in high humidity and heavy pollution environments. 2. Good high-speed operation performance and reliability. 3. Excellent high and low temperature resistance, normal operation in -40~150℃ environment. 4. The product uses high-performance grease imported from abroad, which reduces product noise and increases product service life.

Motor bearings

Drive motor bearings are widely used in automobile drive systems to support the high-speed rotation of the motor rotor shaft. They can withstand impact and vibration loads in harsh high and low temperature environments, while meeting speed performance requirements such as high speed and rapid speed changes. Bearing features: 1. Good high-speed, low-friction torque performance. 2. Good high and low-temperature high-speed lubrication performance, no abnormal noise when running at low temperature. 3. Store more grease, improve the lubrication circuit, and achieve long-term lubrication of the bearing. 4. A hardened layer is formed on the surface of the groove to enhance the surface wear resistance and high temperature tempering resistance, and significantly improve the bearing surface wear resistance. 5. Use high-performance materials combined with structural optimization to effectively improve the bearing's high-low-temperature and high-speed operation stability. 6. Optimize the raceway super-precision process to reduce noise levels.

Transfer case bearings

The speed range of transfer case bearings is generally 300~4000rpm, and the operating temperature range is generally -40~150℃. Such bearings are generally lubricated with oil. The transfer case bearings bear large axial loads and impact loads during operation, and at the same time require the bearings to have low friction torque and to ensure certain stability and reliability. Bearing type: angular contact ball bearing, tapered roller bearing. Bearing features: high load capacity, long life, high reliability, impact resistance.

Gearbox bearings

Bearing types: angular contact ball bearings, spherical plain bearings, tapered roller bearings, four-point contact ball bearings, deep groove ball bearings, cylindrical roller bearings. Bearing features: low noise, high reliability, low friction torque.

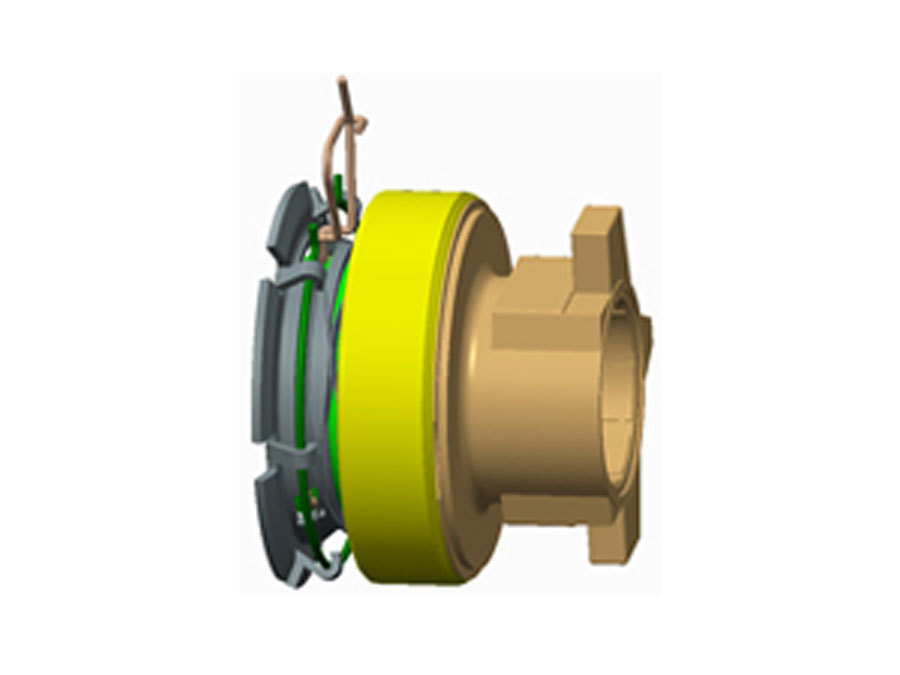

Clutch release bearing

The clutch release bearing is located in the clutch between the engine and the transmission. Its main function is to disengage the clutch through its axial movement, thereby cutting off or transmitting the power output by the engine, and then completing operations such as starting and stopping the car and shifting gears. The clutch bearing has an operating speed range of 1000~3500rpm and an operating temperature range of -40~140℃. As it is located inside the clutch, it is generally lubricated with full sealing grease. Our company has developed a long-life, low-noise automobile clutch automatic self-aligning release bearing through the innovative design of the automatic self-aligning structure based on the wave spring, the high-load-bearing thrust angular contact ball bearing structure and the inner and outer ring processing technology of the bearing. The product has the advantages of low vibration, low noise, light wear and long life (separation times> 2 million times, no bearing failure), etc.

Bearings for reducers

◆ Bearings for automotive reducers are mainly used on the main reducer bevel gear shaft in the axle. The speed range is generally 40~1500rpm, and the operating temperature range is generally -40~120℃. Reducer bearings are generally lubricated with oil. ◆ Bearing type: angular contact ball bearing, tapered roller bearing. ◆ Bearing features: high load capacity, high reliability, and impact resistance.

Wheel bearing

The third-generation product, the integrated inner and outer ring flange, developed by our company, can be directly connected to the suspension or installed on the brake disc and wheel hub by bolts. It has a simpler structure, fewer parts, lighter weight and is very convenient to install. At the same time, most products are integrated with ABS sensor components, making the product structure more compact and lightweight. The products have been widely used in cars and are also gradually expanding their application in trucks.

Share your needs with us and get an impressive collaboration and reassuring product.

Headquarter: East Wing Building, No. 121 Wutong Street, High-Tech Industrial Development Zone, Zhengzhou City, Henan Province, China

No. 1 Factory Address: No. 6 Fenghua Road, Luoyang City, Henan Province, China

No. 2 Factory Address: No. 1 Sanxi Road, Science and Technology Industrial Park, Jianxi District, Luoyang City, Henan Province, China

No. 3 Factory Address: Yibin Industrial Technology Park, Yibin District, Luoyang City, Henan Province, China

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.